High Modulus PolyEthylene rope is one of the strongest, most durable and innovative ropes

on the market today. The rope is made from ultra-high molecular weight polyethylene.

The individual HMPE rope yarns are impregnated with a durable coating to reduce abrasion and extend the service

life. The strength of HMPE rope is comparable diameter/diameter to steel wire rope. Available in two varieties:

Single braided and cover braided rope.

| Relative density | Single braided: 0,97 (floats) Cover braided will vary from 0,97 to 1,15 depending on cover type |

|

| Temperature resistance | Melting point 150°C | |

| UV resistance | Excellent - fully stabilized | |

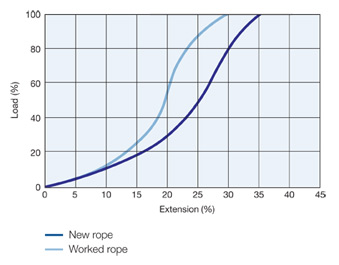

| Extension | 4,5% at break (new rope) reduces to 2% (worked rope) |

|

| Flexibility | Light weight and exible for easy handling - good shape retention | |

| Chemical resistance | HMPE excellent Polyester limited to alkalis |

Length measured under reference tension according to ISO 9554. Minimum breaking load measured according to ISO 2307.

Spliced ropes will on average have 10% lower minimum breaking load. Figures and information are for guidance purpose only.

| Diam. Ø | Mass | Min. breaking load | |

|---|---|---|---|

| mm | kg/100m | T | kN |

| 4 | 0,9 | 1,53 | 14 |

| 6 | 2,3 | 3,77 | 37 |

| 8 | 4 | 6,65 | 65 |

| 10 | 6,1 | 10,4 | 102 |

| 12 | 8,7 | 15 | 147 |

| 14 | 11,7 | 20,4 | 200 |

| 16 | 15,1 | 26,5 | 260 |

| 18 | 19 | 31,6 | 310 |

| 20 | 23 | 38,7 | 380 |

| 24 | 33 | 53 | 520 |

| 26 | 38 | 61,2 | 600 |

| 28 | 45 | 69,3 | 680 |

| 30 | 51 | 78,5 | 770 |

| 32 | 58 | 88,7 | 870 |

| 34 | 65 | 97, | 960 |

| 36 | 72 | 106 | 1040 |

| 38 | 80 | 118 | 1160 |

| 40 | 89 | 128 | 1260 |

| 42 | 98 | 136 | 1330 |

| 44 | 107 | 149 | 1460 |

| 46 | 116 | 163 | 1600 |

| 48 | 126 | 173 | 1700 |

| 50 | 137 | 186 | 1820 |

| 52 | 148 | 201 | 1970 |

| 56 | 171 | 230 | 2260 |

| 60 | 195 | 258 | 2530 |

| 64 | 221 | 290 | 2840 |

| 68 | 248 | 323 | 3170 |

| 72 | 278 | 359 | 3520 |

| 76 | 309 | 397 | 3890 |

| 80 | 343 | 438 | 4300 |

| 82 | 362 | 463 | 4541 |

| 88 | 417 | 530 | 5200 |

| 96 | 496 | 630 | 6180 |

| 104 | 586 | 723 | 7090 |

| 112 | 679 | 831 | 8150 |

| Diam. Ø | Mass | Min. breaking load | |

|---|---|---|---|

| mm | kg/100m | T | kN |

| 20 | 27,4 | 27,6 | 271 |

| 22 | 33 | 34,8 | 341 |

| 24 | 38,5 | 41 | 402 |

| 26 | 44 | 48 | 471 |

| 28 | 51,7 | 56 | 549 |

| 30 | 58,1 | 65 | 637 |

| 32 | 65,7 | 75 | 736 |

| 34 | 73,2 | 84 | 824 |

| 36 | 80,6 | 93 | 912 |

| 38 | 89,2 | 103 | 1010 |

| 40 | 98,8 | 116 | 1140 |

| 44 | 118 | 141 | 1380 |

| 48 | 138 | 164 | 1610 |

| 52 | 161 | 196 | 1920 |

| 56 | 185 | 223 | 2190 |

| 60 | 209 | 257 | 2520 |

| 64 | 236 | 294 | 2880 |

| 68 | 264 | 332 | 3260 |

| 72 | 295 | 370 | 3630 |